Applications and Uses

- Chemical Industries

- Oil & Gas Industrires

- Power Plant Industries

- Shipbuilding Industries

- Fertilizer Industrires

- Petrochemical Industrires

- Sugar Industrires

- Cement Industrires

Aluminium bronze fasteners are a type of fastener made from an alloy of aluminium and bronze. They are recognized for their very high strength, resistance to corrosion, and capacity to sustain extremely high temperatures. Because of these qualities, they are well suited for usage in a wide range of application, including those found in the aerospace, industrial, and maritime industries.

One of the key benefits of aluminium bronze fasteners is their corrosion resistance. They are resistant to corrosion in both freshwater and saltwater environments, making them a popular choice for marine applications. They also have a strong resistance to corrosion from acids and other corrosive substances, which makes them excellent for use in chemical processing facilities and other industrial environments.

In addition to their corrosion resistance, aluminium bronze fasteners also have a high strength-to-weight ratio. They are an excellent choice for applications where weight is a concern because they are much stronger than pure aluminum and lighter than steel. They can also withstand extremely high temperatures, which qualifies them for use in high-temperature environments such as the internal components of aircraft engines and furnaces. There is a wide variety of sizes and designs available for aluminum bronze fasteners so that they can be used for various purposes. They come in many different forms, such as bolts, screws, nuts, and washers, and can be found in various places. They are typically made from an alloy of aluminium and bronze, with the exact composition of the alloy depending on the specific properties required for the application.

Aluminium bronze fasteners are typically made using hot forging or cold heading techniques. Hot forging involves heating the alloy to a high temperature and then using dies and presses to shape it into the desired form. Cold heading involves using a cold-forming process to shape the alloy into the desired shape without the need for heating.

In addition to their corrosion resistance, high strength, and ability to withstand extreme temperatures, aluminium bronze fasteners also have a good resistance to wear and tear. As a result, they are suitable for use in applications in which they may be subjected to high levels of mechanical stress or movement, such as in moving parts or joints. This makes them suitable for use in applications.

Overall, aluminium bronze fasteners are a reliable and durable choice for a wide range of applications where corrosion resistance, high strength, and ability to withstand extreme temperatures are important. They find widespread application in the industrial, aerospace, and maritime sectors, and are offered in a wide variety of dimensions and designs to accommodate a variety of applications.

| Grade | Aluminium Bronze |

| Specification | ASTM |

| Standards | ASTM B 111 C60800/ASME SB 111 C 60800 /EN 12451 CuAL5AS / CW200 / C61400 / C95400 / C61800 / C62300 / C62400 / C62500 / C95200 / C95900 / CuAL11Ni5Fe5, BS1400-AB1 & AB2, BS2874 CA104 & Ca103 / CW300G/ CW303G |

| Size | 1/4″ to 2″ |

| Aluminium Bronze Bolts Size | M8 TO M36 | Custom Sizes |

| Length | UPTO 5 METERS |

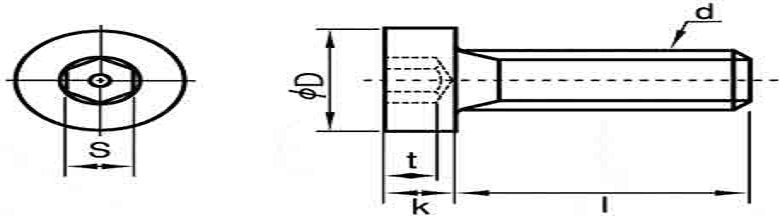

| Form | Bolts, Nuts, Screw, Washers |

| Types | Flange Bolts, Hex Bolts, Lag Bolts, Hex Head Bolts, Eye Bolts, Square Bolts, T Bolts, U Bolts, Hex Head Nut, Counter sunk Bolts, Dome Nut, Coupling Nut, Eye Nut, Acorn Nut, Square Nut, Socket Set Screws, Hex Head Cap Screws, Socket Head Screws, Anchor Screws, Shoulder Screws, Concrete Screws, Machine Screws, Threaded Screws, Flat Washer, Machine Washers, Sealing Washer, Star Washers, Lock Washer etc. |

| CDA | ASTM | ASARCON | SAE | AMS | Federal | Military | Other |

|---|---|---|---|---|---|---|---|

| C95400 | B505 | QQ-C-390, G5; QQ-B-671, CLASS 3 |

MIL-B-16033, CLASS 3 | ALUMINUM BRONZE 9C | |||

| C95400 | B505 | QQ-C-390, G5; QQ-B-671, CLASS 3 |

MIL-B-16033, CLASS 3 | ALUMINUM BRONZE 9C | |||

| C63000 | B150-12 | J461 J463 | 4640 | QQ-C-465B AMD1 |

| Chemical Composition Limits | ||||

| Weight % | Cu | Al | Fe | Ni |

| CA 104 | Rem | 8.5 / 11.0 | 4.0 / 5.5 | 4.0 / 5.5 |

| Material | 0.2% Proof Stress (N/mm² ) | Tensile Strength (N/mm² ) | Elongation % | Hardness (HV) |

| CA 104 | 420-500 | 720-820 | 25-15 | 200-240 |

| Nominal Diameter And TPI (Inches) | Thread Stress Area (Sq. In.) | Grade 2 | Grade 5 | Grade 8 | |||

| Clamp Load 60-90% Proof (Pounds) |

Tightening Torque (Ft.-Lbs.) |

Clamp Load 60-90% Proof (Pounds) |

Tightening Torque (Ft.-Lbs.) |

Clamp Load 60-90% Proof (Pounds) |

Tightening Torque (Ft.-Lbs.) |

||

| 1/4 – 20 1/4 – 28 |

0.0318 0.0364 |

1,049 – 1,574 1,201 – 1,802 |

4 – 7 5 – 8 |

1,622 – 2,433 1,856 – 2,785 |

7 – 10 8 – 12 |

2,290 – 3,434 2,621 – 3,931 |

10 – 14 11 – 16 |

| 5/16 – 18 5/16 – 24 |

0.0524 0.0580 |

1,729 – 2,594 1,914 – 2,871 |

9 – 14 10 – 15 |

2,672 – 4,009 2,958 – 4,437 |

14 – 21 15 – 23 |

3,773 – 5,659 4,176 – 6,264 |

20 – 29 22 – 33 |

| 3/8 – 16 3/8 – 24 |

0.0775 0.0878 |

2,558 – 3,868 2,897 – 4,346 |

16 – 24 18 – 27 |

3,953 – 5,929 4,478 – 6,717 |

25 – 37 28 – 42 |

5,580 – 8,370 6,322 – 9,482 |

35 – 52 40 – 59 |

| 7/16 – 14 7/16 – 20 |

0.1063 0.1187 |

3,508 – 5,262 3,917 – 5,876 |

26 – 38 29 – 43 |

5,421 – 8,132 6,054 – 9,081 |

40 – 59 44 – 66 |

7,654 – 11,480 8,546 – 12,820 |

56 – 84 62 – 93 |

| 1/2 – 13 1/2 – 20 |

0.1419 0.1599 |

4,683 – 7,024 5,277 – 7,915 |

39 – 59 44 – 66 |

7,237 – 10,855 8,155 – 12,232 |

60 – 90 68 – 102 |

10,217 – 15,325 11,513 – 17,269 |

85 – 128 96 – 144 |

| 9/16 – 12 9/16 – 18 |

0.1820 0.2030 |

6,006 – 9,009 6,699 – 10,049 |

56 – 84 63 – 94 |

9,282 – 13,923 10,353 – 15,530 |

87 – 131 97 – 146 |

13,104 – 19,656 14,616 – 21,924 |

123 – 184 137 – 206 |

| 5/8 – 11 5/8 – 18 |

0.2260 0.2560 |

7,458 – 11,187 8,448 – 12,672 |

78 – 117 88 – 132 |

11,526 – 17,289 13,056 – 19,584 |

120 – 180 136 – 204 |

16,272 – 24,408 18,432 – 27,648 |

170 – 254 192 – 288 |

| 3/4 – 10 3/4 – 16 |

0.3340 0.3730 |

11,022 – 16,533 12,309 – 18,464 |

138 – 207 154 – 231 |

17,034 – 25,551 19,023 – 28,535 |

213 – 319 238 – 357 |

24,048 – 36,072 26,856 – 40,284 |

301 – 451 336 – 504 |

| 7/8 – 9 7/8 – 14 |

0.4620 0.5090 |

15,246 – 22,869 16,797 – 25,196 |

222 – 334 245 – 367 |

23,562 – 35,343 25,959 – 38,939 |

344 – 515 379 – 568 |

33,264 – 49,896 36,648 – 54,972 |

485 – 728 534 – 802 |

| 1 – 8 1 – 14 |

0.6060 0.6790 |

19,998 – 29,997 22,407 – 33,611 |

333 – 500 373 – 560 |

30,906 – 46,359 34,629 – 51,944 |

515 – 773 577 – 866 |

43,632 – 65,448 48,888 – 73,332 |

727 – 1,091 815 – 1,222 |

| 1-1/8 – 7 1-1/8 – 12 |

0.7630 0.8560 |

25,179 – 37,769 28,248 – 42,372 |

472 – 708 530 – 794 |

33,877 – 50,816 38,006 – 57,010 |

635 – 953 713 – 1,069 |

54,936 – 82,404 61,632 – 92,448 |

1,030 – 1,545 1,156 – 1,733 |

| 1-1/4 – 7 1-1/4 – 12 |

0.9690 1.0730 |

31,977 – 47,966 35,409 – 53,114 |

666 – 999 738 – 1,107 |

43,024 – 64,535 47,641 – 71,462 |

896 – 1,344 993 – 1,489 |

69,768 – 104,652 77,256 – 115,884 |

1,454 – 2,180 1,610 – 2,414 |

| Aluminium Bronze Alloy Nuts Type | SIZE | PROPERTY CLASS | STANDARD |

|---|---|---|---|

| Aluminium Bronze Hex Nut | M6 to M42 | 10 | ISO 4032 |

| C61400 Aluminum Bronze Nylock Nut | M6 to M20 (Gr.8) M10 to M24 (Gr.10) |

8 & `10 | DIN 982 |

| C63000 Aluminum Bronze Nylock Nut | M6 to M20 (Gr.8) M10 to M24 (Gr.10) |

8 & 10 | DIN 985 |

| C614 Aluminum Bronze Hex Weld Nut | M6 to M12 | 8 | DIN 929 |