Applications and Uses

- Chemical Industries

- Oil & Gas Industrires

- Power Plant Industries

- Shipbuilding Industries

- Fertilizer Industrires

- Petrochemical Industrires

- Sugar Industrires

- Cement Industrires

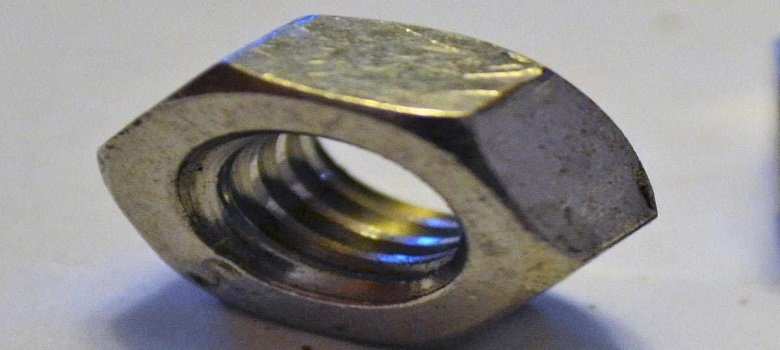

The Nickel nuts are used for the purpose of making non-permanent joints. And these also have great toughness. Nickel 200/201 nuts have good mechanical constants. They are also resistant to a wide range of environments that might be subjected to adverse temperatures. These nickel nut grades are employed in terms of inorganic and organic compounds. And also have a high resistance to most harsh chemicals.

The Nickel 200/201 nuts also have great resistance to corrosion and its related damages. The Nickel 200/201 nuts also show great performance at highly elevated temperatures. These also possess high strength and toughness properties. These nuts also have the property of being durable. Nickel 200/201 nuts have good finishing. The Nickel 200/201 nuts also have the characteristic of being weldable.

Nickel 200/201 nuts also have great tensile strength. Also, these have a long service life. They are less maintenance. Nickel 200/201 nuts are manufactured with high-quality raw materials so that high-quality products are produced. They could be available in different shapes, sizes, and dimensions, depending upon the specifications and requirements provided by the client and the need of the application.

The Nickel 200/201 nuts are manufactured by considering all the industrial standards and guidelines and the necessary rules and regulations to produce high-quality products. Also, as these Nickel 200/201 nuts have all these properties and characteristics, they are used in a wide range of industrial applications. These include food processing, equipment exposed to acids, marine and saltwater equipment, etc.

| Specification | ASTM B 160 ASME SB 160, UNS 2200 Nuts |

| Standard | DIN, UNI, ISO, JIS, GB, IS, BS, ASME, ANSI, ASTM and all International Standards |

| Size | M2, M2.5, M3, M4, M5, M6, M8, M10, M12, M14, M16, M20, M24, M30, M36 to M160 | Custom Sizes |

| Length | 3 mm to 200 mm | Custom Sizes |

| Dimensions | DIN 931, 933, 934, 7991, 976, 125, ASME B18.2.1, B18.3 |

| Form | Hex, Threading, Square, Round as per Gauge Etc. |

| Threads | Unless otherwise specified, the threads shall be rolled or cut and tapped horizontally or vertically |

| Threads available | UNF, BSW, BSF, METRIC, UNC, or as required |

| Threads Configuration |

ASME B1.1 2A/3A – 2B/3B Inch Unified Threads and B1.13M 6h-6G Metric Coarse Threads |

| Certification | Dual Certified As per ASTM & ASME Codes |

| Test Certificate | As per EN 10204 / 3.1 Manufacturer Test Certificate, PED 97/23/EC Certified, Merkblatt AD 2000 W2 Certified |

| Raw materials Source | JSPL, Mukund Steel, Tata Steel, Dhamm Steel, Usha Martin,etc. |

| Packing | IN BULK: canton, pallet, Small Boxs / carton / pallet, or customer request |

| Surface Coating |

Cadmium Coating Hot Dipped Galvanizing Coating Ptfe Coated Phosphate Coating Teflon Coating Xylon Coating Zinc Coating |

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| Nickel 200 | 2.4066 | N02200 | NW 2200 | NA 11 | НП-2 | N-100M | Ni 99.2 |

| Nickel 201 | 2.4068 | N02201 | NW 2201 | NA 12 | НП-2 | - | LC-Ni 99 |

| Grade | C | Mn | Si | S | Cu | Fe | Ni |

| Nickel 200 | 0.15 max | 0.35 max | 0.35 max | 0.01 max | 0.25 max | 0.40 max | 99.0 min |

| Nickel 201 | 0.02 max | 0.35 max | 0.35 max | 0.01 max | 0.25 max | 0.40 max | 99.0 min |

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Nickel 200 / 201 | 8.9 g/cm3 | 1446 °C (2635 °F) | Psi – 67000 , MPa – 462 | Psi – 21500 , MPa – 148 | 45 % |